Desiccant Compressed Air Dryers

Keeping Dew Points Low Since 1944

Portable Compressed Air Dryers

When it comes to supplying portable compressed air dryers, Van Air Systems is unparalleled in the industry. Because we design our units around the use of desiccants that we manufacture in-house, this has allowed us to test our designs for function, durability, and duration over the entire lifespan of the unit. Other factors to consider when purchasing a portable compressed air dryer are overall dimensions of the unit, aftercooler dimensions, and a warranty. Van Air Systems units are robust in design, having a sturdy construction complete with a skid style base for easier transportation between sites. Our portable solutions feature an oversized aftercooler and air operated fan motor, eliminating the need for electricity on location to power the dryer. Lastly, Van Air Systems portable air dryers are designed for the long haul, and come complete with an industry leading warranty.

Single Tower Deliquescent

Van Air Systems D-Series Compressed Air Dryers are single tower deliquescent compressed air dryers for stationary applications. D-Series Dryers remove harmful water vapor from compressed air lines. Wet compressed air enters the bottom of the dryer and flows upward through a bed of deliquescent desiccant, which absorbs moisture as it slowly dissolves. Condensate drops to the bottom of the vessel to be drained. Dry compressed air exits the top of the vessel. When used with Dry-O-Lite desiccant, the D-Series Compressed Air Dryer automatically provides a dew point that is approximately 20°F lower than temperature of the air at the vessel…

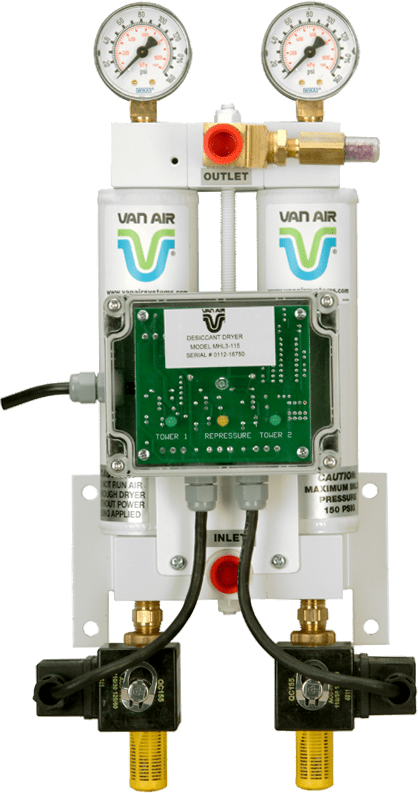

Mini Heatless

MHL-3 through MHL-50 are compact, simple to install, and easy to maintain. These dryers deliver a -40°F pressure dew point to protect pneumatic equipment and processes from the harmful and costly effects of moisture. When treating small volumes of compressed air, an MHL series heatless regenerative desiccant compressed air dryer can deliver dew points down to -100°F in critical applications. Clean and dry compressed air keeps the most vital pneumatic equipment and processes operating smoothly and efficiently.

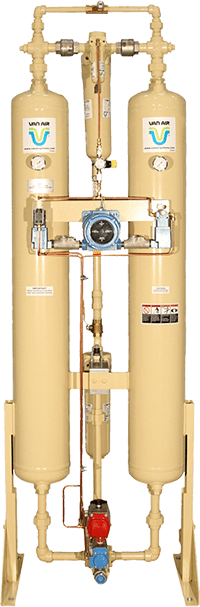

Large Heatless

Engineered for long service life and superior protection of your air-operated equipment and processes, Van Air Systems HL series heatless regenerative desiccant compressed air dryers deliver the peace of mind of high quality, value and fast delivery. All HL series compressed air dryers include patented Interlock Logic valve sequencing to protect compressed air systems from premature loss of flow or pressure. Interlock Logic guarantees that each phase of the drying cycle is completed before the next can begin. This ensures uninterrupted air flow at constant pressure for downstream equipment and prevents accidental vessel re-pressurization, a vital safety feature. HL series…

HLSXA Explosion Proof

Van Air Systems HLSXA regenerative desiccant compressed air dryers deliver extremely dry compressed air in the harshest and most challenging operating environments, where safety and performance are of central importance. HLSXA dryers are explosion proof and have been designed to operate in areas classified as hazardous, Class 1 Division 1, Groups C & D, per the National Electric Code. In the oil & gas and petrochemical industries, operators often rely on compressed air to run essential equipment and instrumentation within confined spaces where explosive gases may be present. In these environments, all equipment must be designed to eliminate the possibility…

In-Line Desiccant Air Dryers

Van Air Systems In-line Desiccant Dryers supply a -40°F pressure dew point and are ideal for pneumatic equipment or instruments that require small volumes of extremely dry compressed air or gas. Van Air offers two types of desiccant cartridges. Model ID15/SW uses a disposable silica gel cartridge. The beads are impregnated with a moisture indicator. A sight window on the body of the dryer is present to view the condition of the silica gel, which turns from blue to pink when saturated with moisture, signaling that it’s time to replace the cartridge. Model ID15/IND uses a disposable molecular sieve cartridge…

Moisture Block

Van Air Systems Moisture Block is the simplest, most cost effective point-of-use compressed air dryer available anywhere. Until now compressed air users in the light industrial market, those using 10 horsepower reciprocating air compressors or smaller, needed to choose between inexpensive dryers with high operating costs or expensive dryers with low operating costs. The Moisture Block is a unique dryer that merges low initial cost and low operating costs. The Moisture Block delivers moisture free air. With the use of activated alumina desiccant it is capable of achieving a -40ºF pressure dew point. The Moisture Block allows you to spray…