Heat: The Phantom Contaminant in Compressed Air

Typically, when customers call Van Air Systems to talk about compressed air and gas treatment products, they are well aware that filters, dryers and drain valves are needed to remove water, oil and particulates. These are the most obvious air system contaminants. Often overlooked, however, is the fact that compressed air is also hot.

Impact of Heat & High Temperature of Compressed Air

I call heat the phantom contaminant because whenever you quiz a customer about the actual compressed air temperature that will be entering a dryer, the response is usually quite vague.

Temperature has a big impact on the sizing and effectiveness of a dryer.

So here is a short refresher on the consequences of temperature and the importance of effective cooling. Cooling compressed air is the first line of defense when protecting an air system from moisture.

So how does water get into a compressed air system? An air compressor takes in ambient air, which always contains water vapor, and compresses it in most cases by a factor of about eight. (A typical 100 PSIG—114.7 PSIA— air system is almost eight times atmospheric pressure at sea level – 14.7 PSIA.) The increased concentration of water vapor raises the dew point. Dew point is the temperature at which condensation begins.

Yet because the compressor also increases the compressed air temperature, water doesn’t begin to condense within the compressor or even in the close-by air piping. Water forms only when compressed air cools after compression.

Remember, hot air “holds” more vapor than cool air. As a rule of thumb, every 20⁰ F change in compressed air temperature will increase or decrease the amount of water that can be “held” in a compressed air system by 50%. This explains why effective cooling removes much of the moisture in a compressed air system. It also explains why ineffective cooling prior to a compressed air dryer has the effect of overloading the dryer.

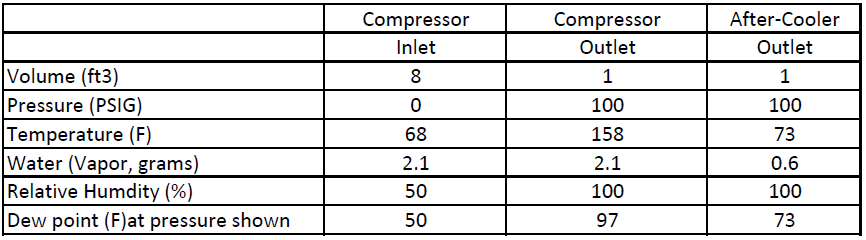

The following chart details the changes in 8 cubic feet of atmospheric air (0 PSIG) as it is compressed to 100 PSIG and subsequently cooled in an after-cooler:

This chart shows that simply by cooling the compressed air to within 5⁰ F of the ambient air temperature, we’ve eliminated over 70% of the moisture taken in by the compressor. (Note: a high efficiency separator with a drain valve needs to be installed immediately after the cooler to actually purge the condensed liquid.) Just by cooling the compressed air with an efficient cooler, the water content of the compressed air has been reduced from 2.1g to 0.6g. This really demonstrates why cooling is such an essential step in compressed air treatment.

There are many techniques for cooling compressed air. It’s common to see a receiver tank or extended piping run used for cooling in lieu of a radiator-type cooler with a fan and motor. I’ve also seen pipes being run outdoors or through a refrigerated room to take advantage of “free” cooling. These are iffy practices, at best.

Many – if not most – air compressors now include an after-cooler within the compression package. However the approach temperature of these packaged coolers is often terrible. It’s typical to see a 25⁰F approach temperature on a packaged cooler. This may not be because the cooler itself is inefficient but simply because, as a piece of the compression package, the cooler is installed within the compressor cabinet or in extreme proximity to the hot compressor.

Also I get the impression that these packaged coolers are sometime designed more for cooling compressor lubricant than for water removal. This problem applies to both stationary electric and diesel portable air compressors.

A properly sized air cooled after-cooler (i.e. radiator + fan + motor) will bring the compressed air temperature to within 5⁰ F of the ambient temperature, condensing most of the water vapor (approximately 70% as we saw in the example above) into a liquid which is removed by a liquid separator.

Remember the cooler is not a dryer. Water will still condense downstream of the after-cooler, since the air remains 100% saturated at this point. Further cooling through expansion and ambient air cooling will cause more condensation. Only the addition of a properly sized and applied compressed air dryer following the after-cooler (and separator) will prevent additional condensation of water vapor.

As they say, it is the little things that matter. But when you are talking about the efficiency of a compressed air system, compressed air temperature is not just a little thing. Effective cooling of hot, compressed air with a properly sized after-cooler (our recommendation is always a 5⁰ F approach temperature to ambient) will significantly improve performance of downstream equipment, reduce operating cost and prevent damage to equipment, processes, and products.

To learn more, visit the product page for our AC Series coolers: https://www.vanairsystems.com/products_after_Air-Cooled.html.

Or call us at 1-800-840-9906.