Air & Gas Dryer Products

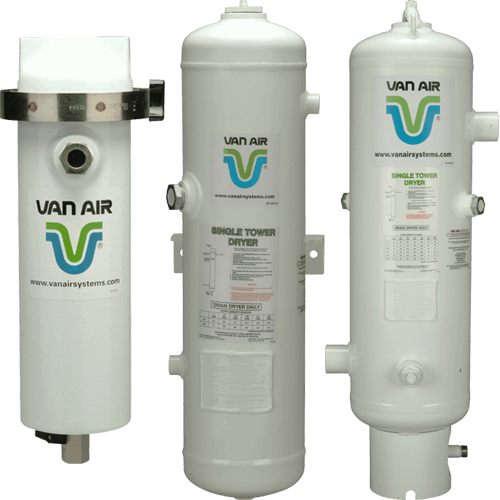

Compressed Air Dryers

Compressed air has applications in virtually all industries. Its uses range from being a reliable source of pneumatic power in manufacturing plants to operating critical instrumentation in process industries. In every application, air quality can be adversely affected by contaminants, such as water, oil and dirt. The result is lower productivity, increased maintenance, and higher operating costs. Van Air Systems compressed air dryers are an affordable and energy-free solution for preventing moisture condensation and freeze-ups in compressed air lines. Trust a high quality, energy-efficient compressed air dryer to keep your air system flowing.

Natural Gas Dryers

Van Air Systems, an industry leader in deliquescent desiccant technology, offers a variety of proven solutions for gas dehydration depending on the application. For removing condensation from pipelines, Van Air offers a full line of deliquescent pipeline dryers for normal operating conditions. For more challenging operating environments, Van Air also offers an explosion proof heatless dryer designed to operate in areas classified as hazardous, Class 1 Division 1, Groups C & D, per the National Electric Code. For jobs on the go, we also offer a skid package that has no moving parts and requires no electricity. Whether drying gas to prevent condensation in pipelines to meet moisture specifications, inhibiting hydrate formation, or simply improving the combustibility of fuel gas, Van Air Systems has a drying package right for you.

Dryer Desiccants

With more than 65 years of experience developing desiccant formulas, Van Air Systems is the leading manufacturer of deliquescent desiccants for drying compressed air and gases. Deliquescent desiccants are a dependable, cost-effective, and energy-free tool for a wide range of drying applications. Van Air Systems is also a leading source for a variety of adsorbent desiccants which include activated alumina, silica gel, and molecular sieve. These desiccants are used in point-of-use and regenerative drying applications.

Portable Solutions

Van Air Systems offers portable compressed air drying solutions for a wide range of applications, from temporary plant back-up to mobile abrasive blasting and painting. The Prep 40 series of air dryers are well suited for plant back-ups, pipeline dehydration and any compressed air application requiring a -40 pressure dew point. The Blast Pak series is perfect for the mobile blasting and painting contractor who needs to keep moisture out of blast pots and nozzles.

Compressed Air & Natural Gas Filters

Contaminants take many forms in compressed air and gas systems. Small particles of atmospheric dust not removed by compressor intake filters are concentrated during compression. Over time, these contaminants will wear out seals, damage sensitive instruments and pneumatic tools, foul heat exchangers, and cause costly downtime. Put Van Air Systems Compressed Air and Natural Gas filters and elements to work and see the difference that clean, trouble free air and gas make in your system.

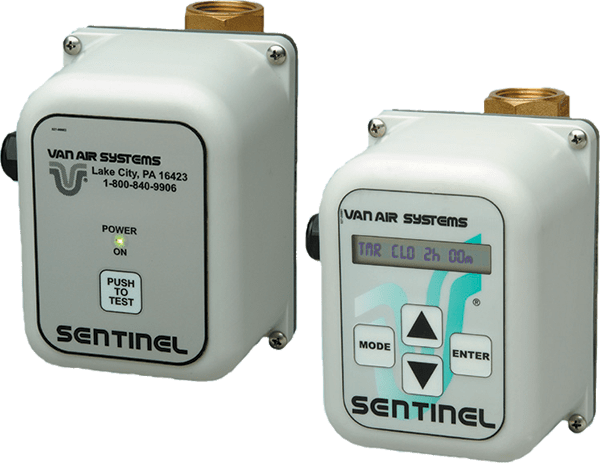

Automatic Drain Valves

Cooling, drying and filtering your compressed air is only part of the air treatment process, draining condensation is the other half. In a 100 scfm system operating at 100 psig in ambient conditions of 70°F and 50% relative humidity, each 8-hour shift produces 2.5 gallons of condensate that must be drained from the system. Van Air Systems offers a variety of sturdy and economical options for automatically draining condensate from your compressed air system.

Natural Gas Filters

Contaminants take many forms in natural gas systems. Small particles of atmospheric dust not removed by compressor intake filters are concentrated during compression. Over time, these contaminants will wear out seals, damage sensitive instruments and pneumatic tools, foul heat exchangers, and cause costly downtime. Put Van Gas Systems filters and elements to work and see the difference that clean, trouble free gas can make in your system.

Compressed Air Filters

Contaminants take many forms in compressed air systems. Small particles of atmospheric dust not removed by compressor intake filters are concentrated during compression. Over time, these contaminants will wear out seals, damage sensitive instruments and pneumatic tools, foul heat exchangers, and cause costly downtime. Put Van Air Systems filters and elements to work and see the difference that clean, trouble free air can make in your system.

Dew Point Monitors for Compressed Air

Excessive moisture in compressed air lines corrodes pneumatic equipment and system piping, normally the most expensive component of an air system. Moisture also contaminates sensitive instruments and processes, leading to preventable downtime. Van Air Systems dew point monitors verify the performance of air dryers by analyzing the water vapor content…

view product

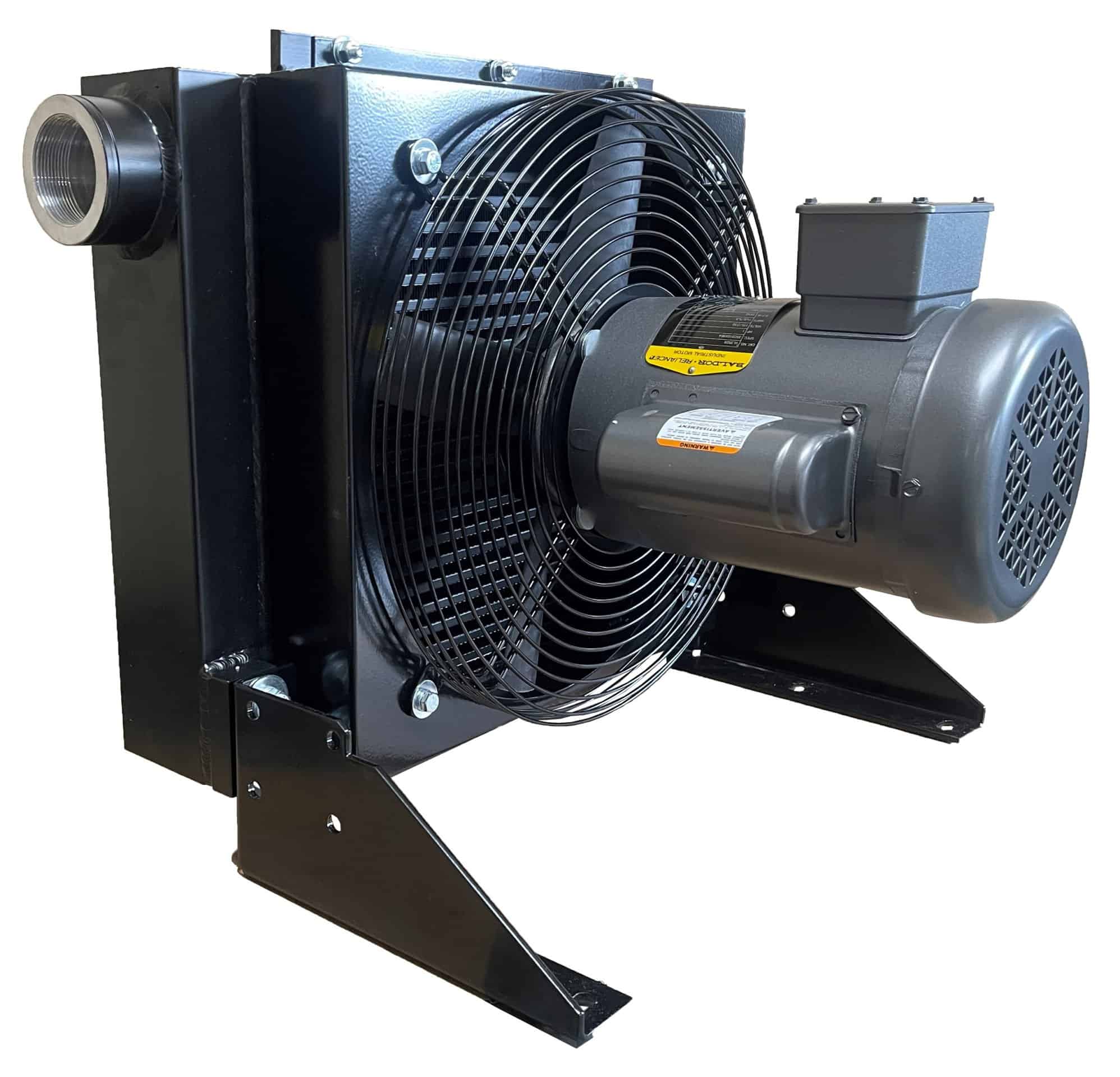

Aftercoolers

Air-cooled aftercoolers for your compressed air system. Van Air Systems Air-Cooled aftercooler offers the best of both worlds in one compact, side by side, combination package. The design features rugged brazed aluminum bar & plate construction with detachable legs for ease of mounting. In a single combined core, the high-performing…

view product

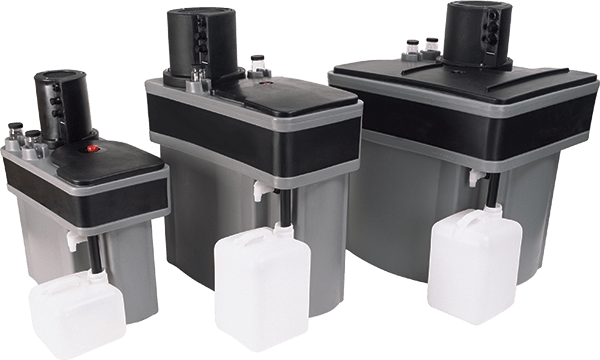

Oil Water Separators

Van Air Systems’ Oil Water Separator series is a cost effective solution to remove lubricating oils from condensate streams. This heavy duty unit is designed to simultaneously process different types of poly glycol oils. These oil water separators are ready for 24 hour continous operation. Van Air Systems’ oil water…

view product